Welcome to visit our website

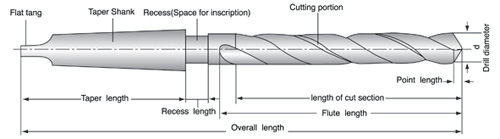

| Main Technical Conditions Of Twist Drill | |||||||||||||||||||

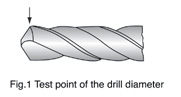

| Drill diameter | |||||||||||||||||||

| The values indicated in the relevant dimensional standards apply in respect of the diameter of Twist Drills. | |||||||||||||||||||

| Test point: On the lands at the corners,(see Fig.l) | |||||||||||||||||||

| |||||||||||||||||||

| Testing equipment: micrometer | |||||||||||||||||||

| Tapering of diameter | |||||||||||||||||||

| The diameter of twist drills usually reduces from the drill tip towards the shank in the area of the flutes. | |||||||||||||||||||

| Test values:The taper on diameter amounts to 0.02 to 0.08mm over a length of 100mm. | |||||||||||||||||||

| Test point: At the outside diameter on the land. | |||||||||||||||||||

| Testing equipment: micrometer and indicating measuring instruments. | |||||||||||||||||||

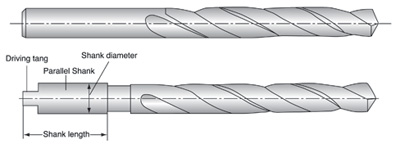

| Parallel shank | |||||||||||||||||||

| Tolerance for shank diameter f11,Tolerance for roundness and parallelism 0.02mm for the shank length. | |||||||||||||||||||

| Concentricity tolorance(Tr.) | |||||||||||||||||||

| The concentricity tolerance(Tr.) of the Twist Drill is calculated from the equation. | |||||||||||||||||||

| Tr=O.03+O.O11/d | |||||||||||||||||||

| In which I is the total length and d the diameter of the drill (all dimensions in mm) | |||||||||||||||||||

| Length | |||||||||||||||||||

| The tolerance of length for the total length corresponds for the degree of accuracy very coarse according | |||||||||||||||||||

| to DIN 7168 part 1.The flute lengths given in the relevant dimensional stands are minimum dimensions. | |||||||||||||||||||

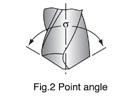

| Point angle | |||||||||||||||||||

| Test value:σ=118°;σ135° | |||||||||||||||||||

| Test point: At the cutting edges(See Fig.2) | |||||||||||||||||||

| Testing equipment: Universal bevel protractor indicating measuring instruments. | |||||||||||||||||||

| |||||||||||||||||||

| Materials and hardness | |||||||||||||||||||

| Materials | |||||||||||||||||||

| M2; M35i M42; F4341; 93410r4341; | |||||||||||||||||||

| Hardness | |||||||||||||||||||

| HSS HRC63-66 | |||||||||||||||||||

| HSSCO HRC64-68 | |||||||||||||||||||

| Test point: On outside diameter on the land or adjacent relieved land. | |||||||||||||||||||

| Test equipment: Hardness Tester. | |||||||||||||||||||

| Making | |||||||||||||||||||

| Twist drills with diameter 3mm and upwards shall be marked with: | |||||||||||||||||||

| Diameter | |||||||||||||||||||

| Material:(HSS;HSSCO;) | |||||||||||||||||||

| Name or mark of manufacturer. | |||||||||||||||||||

| Additional and/or differing marking by agreement. | |||||||||||||||||||

| Twist Drill with parallel shank | |||||||||||||||||||

| |||||||||||||||||||

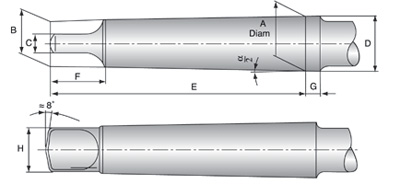

| Twist Drill with taper shank | |||||||||||||||||||

| |||||||||||||||||||

| General dimensions of morse taper shanks | |||||||||||||||||||

| |||||||||||||||||||

| Morse Taper Shank | A mm | B mm | C(h13) mm | D mm | E mm | F(max.) mm | G mm | H(max.) mm | α/2 | ||||||||||

| No.1 | 12.065 | 9 | 5.2 | 12.2 | 62 | 13.5 | 3.5 | 8.7 | 1°25’43 | ||||||||||

| NO.2 | 17.78 | 14 | 6.3 | 18 | 75 | 16 | 5 | 13.5 | 1°25’50 | ||||||||||

| NO.3 | 23.825 | 19.1 | 7.9 | 24.1 | 94 | 20 | 5 | 18.5 | 1°26’16 | ||||||||||

| NO.4 | 31.267 | 25.2 | 11,9 | 31.6 | 117.5 | 24 | 6.5 | 24.5 | 1°29’15 | ||||||||||

| NO.5 | 44.399 | 36.5 | 15.9 | 44.7 | 149.5 | 29 | 6.5 | 35.7 | 1°30’26 | ||||||||||

| NO.6 | 63.348 | 52.4 | 19 | 63.8 | 210 | 40 | 8 | 51 | 1°29’36 | ||||||||||

| Cutting portion | |||||||||||||||||||

| |||||||||||||||||||

| σ= Point angle (sigma) | |||||||||||||||||||

| ψ = Chisel edge angle(psi) | |||||||||||||||||||

| *)In the context of cutting technology, land width b is the body clearance land width which is to be by bfan see | |||||||||||||||||||

| DIN 6581. | |||||||||||||||||||

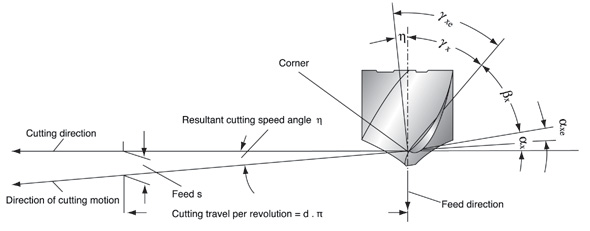

| Angle at the cutting edges | |||||||||||||||||||

The corner has been adopted as the observed edge point The corner has been adopted as the observed edge point | |||||||||||||||||||

| αx=Side clearance angle (alpha) | |||||||||||||||||||

| αxe=Effective side clearance angle | |||||||||||||||||||

| βx=Side wedge angle(beta) | |||||||||||||||||||

| γx=Front rake angle(gamma) | |||||||||||||||||||

| γxe=Working front rake angle | |||||||||||||||||||

| η=Resultant cutting speed angle(eta) | |||||||||||||||||||

| Clearance angle α,wedge angle β and rake angleγare measured in the tool orthogonal plane. For details, | |||||||||||||||||||

| see DIN 6581, definitions of metal-cutting technology; geometry at the tool edge. | |||||||||||||||||||

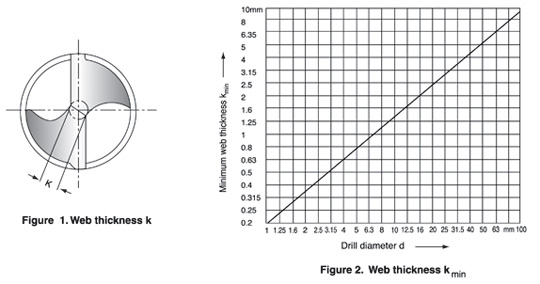

| Web thickness K | |||||||||||||||||||

| Test values:The web thickness according to Fig.1 shall not be less than the minimum value kmin indicated in Fig.2. | |||||||||||||||||||

| Test point: At the point of the drill. | |||||||||||||||||||

| Testing equipment:Slide gauge with measuring points. | |||||||||||||||||||

| |||||||||||||||||||

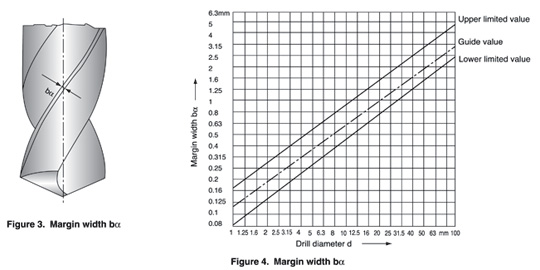

| Margin width bα | |||||||||||||||||||

| Test values: The land width as in Fig.3 shall lie within the limitting values indicated in Fig.4 | |||||||||||||||||||

| Test point: 5mm behind the corner | |||||||||||||||||||

| Testing equipment: Slide gauge | |||||||||||||||||||

| |||||||||||||||||||

| Angle on twist drills | |||||||||||||||||||

| (1)Side rake angle γf (Helix angle) | |||||||||||||||||||

| Recommended test value: Recommended ranges depending on the tool types N,H and W according to DIN 1836 | |||||||||||||||||||

| and the diameter of the drill included in Fig.5 | |||||||||||||||||||

| Test point: At the corner, see Fig.6 | |||||||||||||||||||

| Testing equipment: According to VDI Guideline 3331 Part1 ,Section Margin widthbα | |||||||||||||||||||

| Note:The side rake angle γfis measured in place of the orthonagonal rake angle γo found in the wedge measuring | |||||||||||||||||||

| plane(see DIN 6581),as this changes along the cutting edge(becoming smaller towards the point of the drill) | |||||||||||||||||||

| (2) Point angle σ | |||||||||||||||||||

| test value: Usual executin for tool types N and H:σ =118°,for tool type W:σ =130° | |||||||||||||||||||

| Test point: At the cutting, see Fig.7. | |||||||||||||||||||

| Testing equipment: According to VDI Guideline 3331 Part 1, Section Margin width bα | |||||||||||||||||||

| Resharpening Twist drills | |||||||||||||||||||

| (1) Drills are worn off irregularly.It should be sharpened prior to developing into excessive wear. | |||||||||||||||||||

| (2) Resharpening | |||||||||||||||||||

| ①Grind the correct point angle to suit your application.(figure 8) | |||||||||||||||||||

| ②Check that both cutting lips have the same angle. On a 130° point,each lip should be 65° toward the axis. | |||||||||||||||||||

| The point must be on center, i.e.,the chisel edge must produce cutting lips of equal length.(figure 8) | |||||||||||||||||||

| ③Grind Primary relief and Secondary clearance,(figure 9) | |||||||||||||||||||

| ④Grind web thinning.(figure 10) | |||||||||||||||||||

| Web Thinning | |||||||||||||||||||

| (1) Without thinning | |||||||||||||||||||

| Suitable for drill of general purpose.Thanks to thin web thickness, web thinning is not need. | |||||||||||||||||||

| This without web thinning type is applied to design of drills for mild steel, alloy steels, cast iron, stainless steel, | |||||||||||||||||||

| titanium, inconel, etc. and conventional cutting conditons. | |||||||||||||||||||

| (2) Type C thinning (DIN 1412 FORM C,SPLIT POINT) | |||||||||||||||||||

| Because Split point enables good centering | |||||||||||||||||||

| when drilling and breaks the chips,chip removals is easy. | |||||||||||||||||||

| Suitable for drill design in high hardened tough materials,i.e, heat treated steel, titanium alloy, stainless steel, | |||||||||||||||||||

| incoroy inconel, nimonic, etc. | |||||||||||||||||||

| (3) Type R thinning (HEI.ICAL THINNING) | |||||||||||||||||||

| Helical thinning ensure to frequent chip breaking and removal. The different direction force of cutting edges and | |||||||||||||||||||

| helical thinning parts enables that chips curl, break and remove through the flutes. In addition helical thinning | |||||||||||||||||||

| makes the chip room up to center, remove the chisel and enables good centering. | |||||||||||||||||||

| (4)Type A thinning (DIN1412 FORM A) | |||||||||||||||||||

| A type thinnings makes thin chisel, good chip removal and favorable centering. | |||||||||||||||||||

| This type is the easiest type to grind the thinning. In narrow web and wide fluted drills,keeping of the rigidity and | |||||||||||||||||||

| smooth chip removal are possible. | |||||||||||||||||||

| (5) Type B thinning (DIN1412 FORM B) | |||||||||||||||||||

| In case of work materials with low cutting resistance and good chip removal,ie,cast iron,aluminium, plastic etc, B | |||||||||||||||||||

| type thinning is suitable. Especially when drills for high hardended steels are designed, this type is applied to | |||||||||||||||||||

| decrease rake angle and avoid chipping of cutting lips. | |||||||||||||||||||

| The Industry`s Most Verstile Deep Hole Drill | |||||||||||||||||||

| The wide land parabolic design provides greater strength and rigidity while wllowing move | |||||||||||||||||||

| flute area to accommodate chip flow.The stronger cross section allows to handle a wider | |||||||||||||||||||

| variety of medium to heavy-duty applications.The benfits of the design include; | |||||||||||||||||||

| Improved coolant flow to point | |||||||||||||||||||

| Reduced machining time;less retooling and downtime | |||||||||||||||||||

| Closer hole tolerances | Length | ||||||||||||||||||

| Reduced torque levels | Jobber | ||||||||||||||||||

| Reduced chip congestion | Screw Machine | ||||||||||||||||||

| Deep Hole drills are offered in a length, material and finish for your application | Taper | ||||||||||||||||||

| Refer to the Technical Data (pgs. 14-15) for oPerating parameters. | Extra Length | ||||||||||||||||||

| Construction Comparison | |||||||||||||||||||

| Deep Hole Drills | Finish | Material | |||||||||||||||||

| 135° split point | Surface Treated | HSS | |||||||||||||||||

| Increased flute area allows more room for chip evacuation | Bright | HSS | |||||||||||||||||

| Reduced margin width reduces heat generation | TiN Coated | HSS | |||||||||||||||||

| Wider land provides increased strength and rigidity | BRONZE | COBALT | |||||||||||||||||

| Performs best in alloyed steels | TIIALN | COBALT | |||||||||||||||||

| Standard Parabolic Drills | |||||||||||||||||||

| 135° split point | |||||||||||||||||||

| Standard parabolic flute area | |||||||||||||||||||

| Standard margin | |||||||||||||||||||

| Narrow land | |||||||||||||||||||

| Performs best in mild steels | |||||||||||||||||||

| 135° Split-Point, Heavy-Duty, TiN-Coated | |||||||||||||||||||

| Size | Decimal Equivalent | Flute Length | Overall Length | Env. Qty. | |||||||||||||||

| 1/16 | 0.0625 | 7/8 | 1/16 | 12 | |||||||||||||||

| 5/64 | 0.0781 | 1 | 5/65 | 12 | |||||||||||||||

| 3/32 | 0.0938 | 1-1/4 | 3/32 | 12 | |||||||||||||||

| 7/64 | 0.1094 | 1-1/2 | 7/64 | 12 | |||||||||||||||

| 1/8 | 0.1250 | 1-5/8 | 2-3/4 | 12 | |||||||||||||||

| 9/64 | 0.1406 | 1-3/4 | 2-7/8 | 12 | |||||||||||||||

| 5/32 | 0.2188 | 2 | 3-1/8 | 12 | |||||||||||||||

| 11/64 | 0.1719 | 2-1/8 | 3-1/4 | 12 | |||||||||||||||

| 3/16 | 0.1875 | 2-5/16 | 3-1/2 | 12 | |||||||||||||||

| 13/64 | 0.2031 | 2-7/16 | 3-5/8 | 12 | |||||||||||||||

| 7/32 | 0.2188 | 2-1/2 | 3-3/4 | 12 | |||||||||||||||

| 15/64 | 0.2344 | 2-5/8 | 3-3/7 | 12 | |||||||||||||||

| 1/4 | 0.2500 | 2-3/4 | 4 | 12 | |||||||||||||||

| 17/64 | 0.2656 | 2-7/8 | 4-1/8 | 12 | |||||||||||||||

| 9/32 | 0.2812 | 2-15/16 | 4-1/4 | 12 | |||||||||||||||

| 19/64 | 0.2969 | 3-1/16 | 4-3/8 | 12 | |||||||||||||||

| 5/16 | 0.3125 | 3-3/16 | 4-1/2 | 6 | |||||||||||||||

| 21/64 | 0.3281 | 3-5/16 | 4-5/8 | 6 | |||||||||||||||

| 11/32 | 0.3438 | 3-7/16 | 4-3/4 | 6 | |||||||||||||||

| 23/64 | 0.3594 | 3-1/2 | 4-7/8 | 6 | |||||||||||||||

| 3/8 | 0.3750 | 3-5/8 | 5 | 6 | |||||||||||||||

| 25/64 | 0.3906 | 3-3/4 | 5-1/8 | 6 | |||||||||||||||

| 13/32 | 0.4062 | 3-7/8 | 5-1/4 | 6 | |||||||||||||||

| 27/64 | 0.4219 | 3-15/16 | 5-3/8 | 6 | |||||||||||||||

| 7/16 | 0.4375 | 4-1/16 | 5-1/2 | 6 | |||||||||||||||

| 29/64 | 0.4531 | 4-3/16 | 5-5/8 | 6 | |||||||||||||||

| 15/32 | 0.4688 | 4-5/16 | 5-3/4 | 6 | |||||||||||||||

| 31/64 | 0.4844 | 4-3/8 | 5-7/8 | 6 | |||||||||||||||

| 1/2 | 0.5000 | 4-1/2 | 6 | 6 | |||||||||||||||

|

|||||||||||||||||||

| Material Application Chart | |||||||||||||||||||

| Finish | Range of Application details | ||||||||||||||||||

| Black/Bronze Oxide | Iron,Steel,Stainless Steel,Wood | ||||||||||||||||||

| 135 Split-Point for quick penetration and reduced walking | |||||||||||||||||||

| Premium-grade M-7 industrial steel and super hard performance coating for longer, heat resistance and easier drilling | |||||||||||||||||||

| Unique flute design for superior material removal | |||||||||||||||||||

| Heavy-duty construction provides additional strength | |||||||||||||||||||

| Designed for enhanced performance in medium-and high-tensile strength alloy materials | |||||||||||||||||||

| Size | Flute Length | Overall Length | |||||||||||||||||

| 0.5 | 22 | 6 | |||||||||||||||||

| 1 | 34 | 12 | |||||||||||||||||

| 1.5 | 40 | 18 | |||||||||||||||||

| 2 | 49 | 24 | |||||||||||||||||

| 2.5 | 57 | 30 | |||||||||||||||||

| 3 | 61 | 33 | |||||||||||||||||

| 3.5 | 70 | 39 | |||||||||||||||||

| 4 | 75 | 43 | |||||||||||||||||

| 4.5 | 80 | 47 | |||||||||||||||||

| 5 | 86 | 52 | |||||||||||||||||

| 5.5 | 93 | 57 | |||||||||||||||||

| 6 | 93 | 57 | |||||||||||||||||

| 6.5 | 101 | 63 | |||||||||||||||||

| 7 | 109 | 69 | |||||||||||||||||

| 7.5 | 109 | 69 | |||||||||||||||||

| 8 | 117 | 75 | |||||||||||||||||

| 8.5 | 117 | 75 | |||||||||||||||||

| 9 | 125 | 81 | |||||||||||||||||

| 9.5 | 125 | 81 | |||||||||||||||||

| 10 | 133 | 87 | |||||||||||||||||

| 10.5 | 133 | 87 | |||||||||||||||||

| 11 | 142 | 94 | |||||||||||||||||

| 11.5 | 142 | 94 | |||||||||||||||||

| 12 | 151 | 101 | |||||||||||||||||

| 12.5 | 151 | 101 | |||||||||||||||||

| 13 | 151 | 101 | |||||||||||||||||